Açıklama

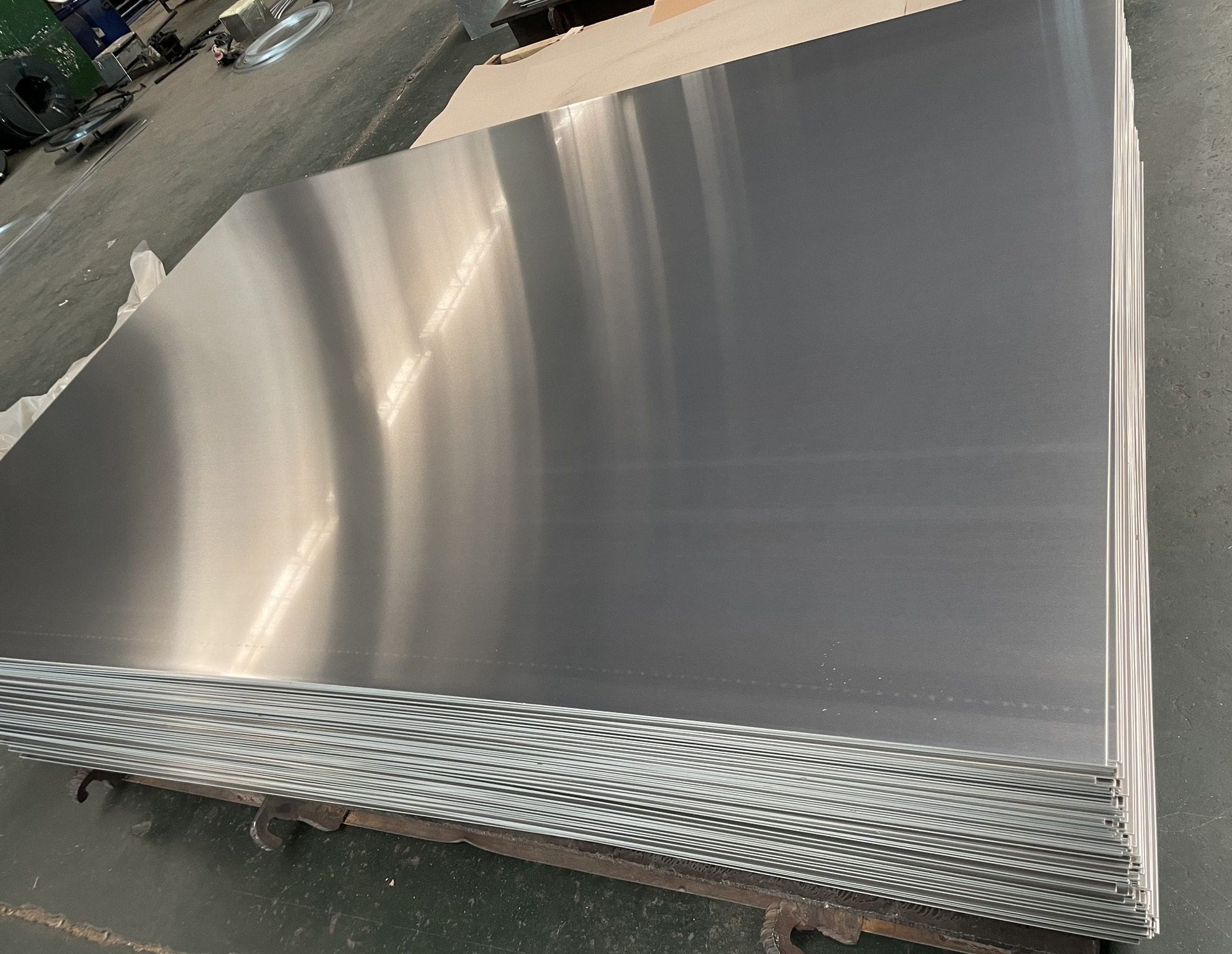

7075 aluminum sheet is a high-strength aerospace aluminum alloy that is commonly used in the manufacture of aircraft and other high-stress applications.

It has excellent strength-to-weight ratio and is resistant to stress corrosion cracking. The alloy is available in various thicknesses and sizes, and can be easily machined and formed. It is also heat treatable, which allows for further strengthening of the material.

7075 Alüminyum levha is typically used in the construction of aircraft wings, gövde çerçeveleri, and other structural components. It is also used in the manufacturing of high-performance sporting equipment, such as bicycle frames and rock climbing gear.

Alüminyum levha / Plaka 7075-T6/T651 normalde havacılık için kullanılır, askeri, ve otomotiv uygulamaları. 7075 alüminyum is the strongest aluminum, birçok çeliğin gücüyle, alüminyumun hafif niteliklerini ve korozyon direncini korurken.

| alaşım | öfke | Kalınlık | Genişlik |

| 7075 | T651 | 4-260aa | 1200-3800aa |

| 7075 | T7651 | 4-260aa | 1200-3800aa |

| 7075 | T7351 | 4-260aa | 1200-3800aa |

Mekanik özellikler

| alaşım durumu | Yön | Kalınlık (aa) | Gerilme direnci | Akma dayanımı | kopma uzaması | Standart |

| 7075-T651 | LT | 6-260 | 570-590mpa | 495-515mpa | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560mpa | 480-490mpa | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520mpa | 420-435mpa | 10-12.5 | AMS4078 |

Alüminyum 7075 üyesidir 7000 dizi, Ana alaşım bileşeni olarak çinko içeren ve olağanüstü yüksek mukavemeti ile bilinen. Temperleme işlemi daha sonra yüksek mekanik mukavemetini daha da artırabilir. Bu özellik alaşım yapar 7075 havacılık ve savunma endüstrilerinde çok popüler.

| Tipik Mekanik Özellikleri 7075 Alüminyum Levha | ||||

| öfke | Kalınlık

(aa) |

Gerilme direnci

(mpa) |

Akma dayanımı

(mpa) |

Uzama

(%) |

| T6 | 1~3.2 | 540 | 470 | 8 |

| T6 | 3.2~6.3 | 540 | 475 | 8 |

| T651 | 6.3~12.5 | 540 | 460 | 9 |

| T651 | 25~50 | 530 | 460 | — |

| T651 | 60~80 | 495 | 420 | — |

| T651 | 90~100 | 460 | 370 | |

Gücü, birçok çelik türüyle karşılaştırılabilir, ama çok daha düşük bir yoğunluğa sahip. Alaşım, yüksek gerilimli uygulamalarda çeliğe mükemmel bir alternatiftir. Ayrıca yorgunluk stresine dayanmada da üstündür., çok güvenilir hale getirmek, yukarıda belirtilen endüstrilerde çok aranan bir kalite.

alaşım 7075 sadece ortalama korozyon direnci sunar, kimyasal bileşiminde bulunan az miktarda bakırın bir sonucu. Ayrıca makul işlenebilirlik ve zayıf şekillendirme ve kaynaklanabilirlik özelliklerine sahiptir.. Bu alaşımın bir başka dezavantajı, olağanüstü yüksek mukavemeti nedeniyle diğer alüminyum alaşımlarına göre nispeten yüksek bir maliyete sahip olmasıdır..

RAYIWELL MFG or RuiYi Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Quality could full meet AMS aviation standard.

Standart

Bare: AMS QQ-A-250/12, BS 2 L95, AMS 4038, AMS 4045, AMS 4039, AMS 4049, AMS 4044, AMS 4045, AMS 4078, QQ-A-250/24, AIR 9048.690, AIR 9048.700, AIR 9048.710, AIR 9049, vb.

AlClad: AMS QQ-A-250/13, BS 2 L88, AMS 4046, AMS 4048, AMS 4049, QQ-A-250/18, QQ-A-250/25, QQ-A-250/26, vb.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

In what application scenarios can 7075 aluminum alloy not replace other materials?

7075 alüminyum levha ve aluminum rods are important members of aluminum alloy materials. They are widely used in many fields due to their high strength, iyi mekanik özellikler, excellent corrosion resistance and wear resistance.

First of all, 7075 aluminum alloy is a high-strength heat-treatable alloy. Its strength is far greater than that of ordinary hard aluminum, and it has excellent weldability and corrosion resistance. This makes it irreplaceable in aerospace, otomobil üretimi, shipbuilding and other fields.

In the aerospace field, 7075 aluminum sheet plate and aluminum rods are often used to manufacture aircraft parts, such as wings, fuselages, engine casings, vb., because they can significantly reduce the weight of aircraft and improve flight performance and fuel economy.

In automobile manufacturing, they are used to make body parts, wheels, suspension systems, vb., aiming to improve the overall performance and fuel economy of the car.

ikinci olarak, 7075 aluminum plates or aluminum sheets and aluminium rods also have good processing performance and wear resistance, which makes them useful in the fields of electronic products and sports equipment manufacturing.

In the field of electronic products, they are used to manufacture electronic equipment casings, heat sinks and other components to improve the heat dissipation efficiency and protection performance of the equipment.

In the manufacturing of sports equipment, 7075 aluminum sheets and aluminum rods are often used to make sports equipment such as hiking poles, bicycle frames, poles, and ski poles due to their lightweight and durable properties.

7075 aluminum alloy is widely used in many fields due to its high strength, wear resistance, mükemmel korozyon direnci, and good electrical and thermal conductivity.

Especially in situations where high material performance requirements are required, 7075 aluminum alloy shows its unique advantages.

Specifically, in the aerospace field, which has extremely high requirements for the strength and corrosion resistance of the material, 7075 aluminum alloy has become an ideal choice due to its excellent performance.

Örneğin, 7075 aluminum alloy plays an irreplaceable role in the manufacturing of key components such as aircraft parts, kanatlar, fuselages and engine casings.

benzer şekilde, in the field of automobile manufacturing, 7075 aluminum alloy materials are often used in components such as high-strength bolts, aluminum alloy cylinders, and automobile bodies.

-

-

-