Sự miêu tả

3105 aluminum coils is a 3000-series aluminum alloy: the main alloying addition is manganese, and it is formulated for primary forming into wrought products. 3105 is the Aluminum Association (AA) designation for this material. In European standards, it will be given as EN AW-3105.

3105 tấm nhôm is 98% pure aluminum with the addition of specific alloys for strength improvement. This alloy can’t be hardened by heat treatment. It has excellent weldability, formability, and corrosion resistance

Nhôm / Nhôm 3105 alloy has average machinability. Tuy nhiên, its machinability can be increased in harder tempers than in annealed condition. Oil lubricants are used for machining this alloy

Nhôm / Nhôm 3105 alloy has good forming characteristics. It is suggested that bend radii should be used in one thickness to 2 t range for annealed H12, H14 and H16 tempers. Bend radii of 2 đến 7 t should be used for the H18 temper

Nhôm / Nhôm 3105 alloy does not react to heat treatment except during cold working.

tâm trạng: F, các, H12, H14, H16, H18, H19, H22, H24, H26, H28, H111, H112, H114

Độ dày:0.2-350mm

Chiều rộng:30-2600mm

Chiều dài:200-11000mm

Cuộn dây mẹ: CC hoặc DC

Cân nặng: Khoảng 2mt mỗi pallet cho kích thước chung

MOQ: 5-10tấn mỗi kích thước

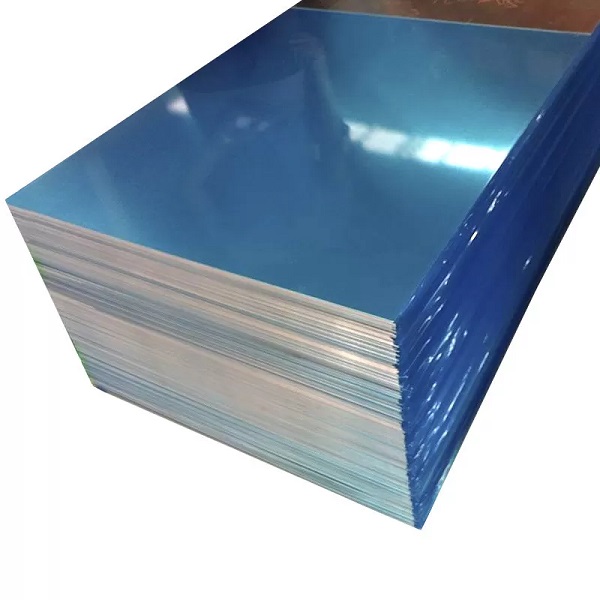

Sự bảo vệ: giấy liên lớp, phim trắng, phim lam tinh, phim đen trắng, phim bị ràng buộc vi mô, theo yêu cầu của bạn.

Bề mặt: sạch và mịn, không có đốm sáng, ăn mòn, dầu, có rãnh, vv.

Sản phẩm tiêu chuẩn: GBT3880, JIS4000, EN485, ASTM-B209, EN573

Thời gian giao hàng: khoảng 30 ngày sau khi nhận được tiền đặt cọc

Thanh toán: T / T, L / C trả ngay

Điều khoản giao dịch: FOB, CIF, CFR

Nhôm / Nhôm 3105 alloy is used in sheet metal work. It is also used in manufacturing mobile homes, siding dân cư, and rain carrying goods.

Other application of 3105 tấm nhôm

Vehicle Bodies

Refrigerated Trucks

Ambulances

Cold Rooms

Anti-skid flooring

Ship platforms

Stair Treads

3105 aluminum sheet is a typical deep drawing materials with good rust resistance, electrical conductivity. 3105 aluminum sheet has excellent weldability, formability.

-

-

-