描述

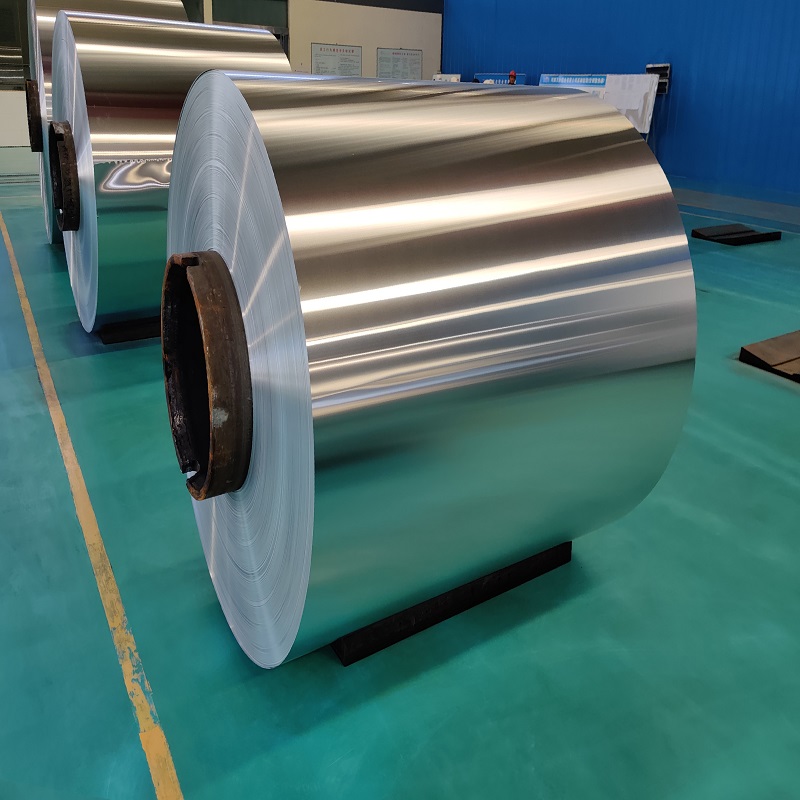

6061 中国制造的铝线圈是经过热处理的加固合金板,具有良好的形成性, 可焊性, 机械加工性, 和中等力量, 退火后可以保持良好的可操作性.

镁铝6061-T651是6系合金的主要合金, 它是一种高质量的铝合金产品,接受热处理和预伸展. 具有易成膜、氧化效果优异等优良特性.

6061 铝线圈 广泛用于需要一定强度和高腐蚀性的各种工业结构零件, 例如制造卡车, 塔式建筑, 船舶, 有轨电车, 铁路车辆.

6061 铝合金 是由热处理和伸展过程产生的高质量铝合金产品. 尽管无法将其强度与2xxx系列或7xxx系列进行比较, 它的镁和硅合金具有许多特征, 出色的处理性能和出色的焊接特性. 和电镀, 良好的耐腐蚀性, 韧性高,加工后不变形, 密集的材料没有缺陷,易于抛光, 易于彩色电影, 出色的氧化效果和其他出色的特征.

主要合金元素 6061 铝合金是镁和硅, 并形成mg2si. 如果其中包含一定数量的锰和铬, 它可以中和铁的不良影响; 有时添加少量铜或锌以提高合金强度,而无需显着降低其耐腐蚀性; 仍然有少量的导电材料. 铜,以抵消钛和铁对电导率的不利影响; 锆或钛可以完善谷物并控制重结晶; 为了提高可加工性, 可以添加铅和二氮. MG2SI在铝中实心溶解, 使合金具有人工衰老硬化功能. 主要合金元素 6061 铝合金是镁和硅, 具有中等强度, 良好的耐腐蚀性, 可焊性, 且氧化效果好.

通用 6061 铝卷 可以热处理, 抵抗应力开裂, 并且易于焊接和机器, 但可成型性受到限制. 6061 铝线圈和铝板非常适合结构框架, 基板, set, 飞机, 海洋和汽车零件, 等等

因为 6061 铝合金易于挤出, 它可以提供各种产品表格,例如表, 条, 盘子, 杆, 锻件, 管, 管道, 电线, 挤出零件和结构形状. 铝 6061 具有良好的耐腐蚀性, 机械性能, 成形性, 可焊性, 和可加工性.

它属于 6000 系列 (的Al-Mg-Si系) 合金铝板,具有良好的可焊性. 与此同时, 6061 铝线圈板具有出色的铝 - 镁组成比和强耐腐蚀性. 硬度是95小时 (布里尔), 易于处理和形式, 不粘刀

6061 铝老化 6061 铝合金板, 板, 滚动或冷的电线, 杆, 酒吧, 并抽油管老化至金属温度 160 °C (320 °f) 并维持18小时. 挤出的杆, 杆, 形状和管; 死去和手的疑问, 滚动环的年龄为金属温度 175 °C (345 °f) 并保留 8 小时

脾气: T1,T2,T3, T4, T6, T651

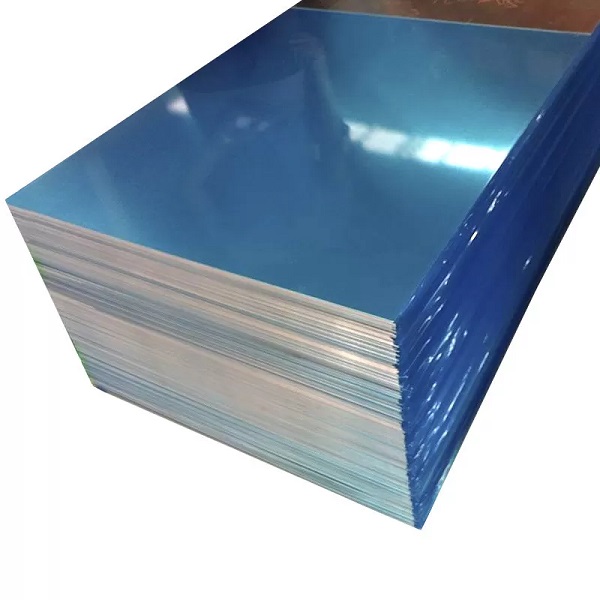

厚度:0.2-350毫米

宽度:30-2600毫米

长度:200-11000毫米

母线圈: 抄送或直流

重量: 一般尺寸每托盘约 2 吨

MOQ: 5-10每尺寸吨

保护: 纸夹层, 白膜, 蓝膜, 黑白胶片, 微胶卷, 根据您的要求.

表面: 干净光滑, 没有亮点, 腐蚀, 油, 开槽, 等等.

标准品: GBT3880, JIS4000, EN485, ASTM-B209, EN573

交货时间: 收到定金后约 30 天

付款: 电汇, 即期信用证

交易条款: 离岸价, 到岸价, 病死率

该 6061 合金是挤出最常见的一种, 但是您可能正在考虑特定应用程序的其他选项. 以下是其他一些常见的合金,通常被视为替代品.

6061 和 6063 是两种最受欢迎的挤压合金. 6063 铝占据了第一名 6061 占据第二名. 作为合金 6000 系列, 他们都有镁和硅作为主要合金元素. 从而, 他们有许多类似的属性. 6061 提供更高的力量, 然而. 像这样, 它通常用于更结构的应用. 6063, 另一方面, 用于栏杆或装饰等应用, 视窗, 和门, 由于其外观更好和耐腐蚀性.

喜欢 6061, 5052 铝具有镁作为主要合金元件. 如果是 5052, 这是唯一的主要合金元素. 6061 也有硅. 该合金的关键好处之一是与其他合金相比,其高水平的可焊接性. 对于可焊接性是关键的项目, 值得考虑. 一个缺点 5052, 尽管, 是不是热处理. 它适用于各种焊接应用,并且由于其高腐蚀性而在海洋应用中效果很好.

主要用于航空应用, 该 2024 合金以高强度而闻名. 它的主要合金元素是铜, 尽管它很强并且具有良好的疲劳性, 它比可加工的不太可加工,更难焊接 6061. 它还具有耐腐蚀性差,并且经常用于高压张力的机翼和机身结构.

一个成员 6000 系列, 6061 铝的主要合金元素是镁和硅, 这是所有交易的杰克的一个很好的例子. 合金有点普遍, 在结构和建筑产品以及航空航天和娱乐行业中看到一些曝光.

合金 6061 显示出良好的拉伸强度, 可以通过脾气治疗改善, 和良好的耐腐蚀性, 可焊性, 和工作性. 它的可加工性使其成为许多挤出项目的正确选择, 因为很容易形成.

合金以相对较低的成本可用,是生产不同形状各种组件的绝佳选择. 虽然合金 6061 在任何铝属性列表中都不排名第一, 这是一种很棒且可靠的全能铝合金.

-

-

-