描述

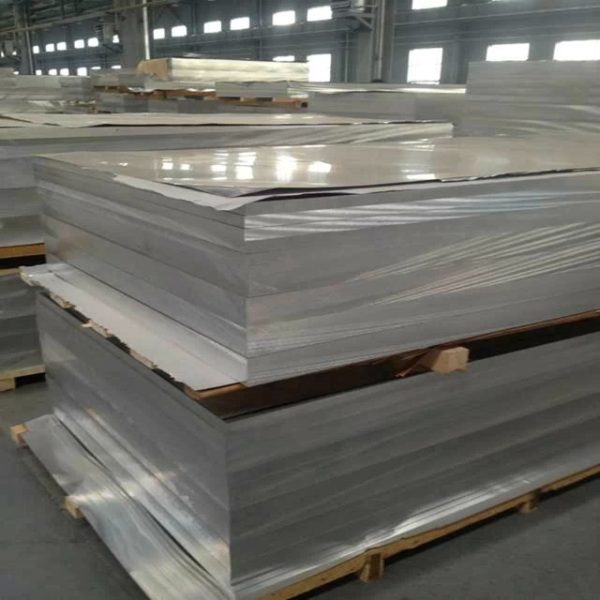

7075 aluminum alloy supplier RAYIWELL is a professional factory of aluminum sheet, 铝棒, 或中国铝板.

铝卷 Aluminum Plate Sheet Supplier 瑞威尔 MFG / RUIYI可以提供以下铝板等级

1000 系列:1050,1060,1070,1080,1100,1145,1200,1235, 等等.

2000 系列:2014,2017,2018,2024,2025,2219, 2219,2618等.

3000 系列:3003,3004,3102,3104,3105,3005, 等等.

4000 系列:4032,4043, 4017, 等等

5000 系列: 5005,5052,5454,5754,5083,5086,5182,5082, 等等.

6000 系列:6061,6063,6262,6101, 等等

7000 系列:7072,7075,7003 等等

7075 aluminum alloy is a cold-processed forged alloy with high strength, much better than mild steel. 7075 is one of the strongest alloys commercially available. General corrosion resistance, good mechanical properties and anodic reaction. Fine grains allow for better deep drilling performance, enhanced tool wear resistance and distinctive thread rolling.

7050 is a high-strength heat-treatable alloy with extremely high strength and resistance to spalling corrosion and stress corrosion cracking. Commonly used in aircraft structural parts for medium and thick plates, extruded parts, free forging parts and die forging parts.

7075 铝板 is an Al-Zn-Mg-Cu series superhard aluminum. 7075 alloy is an ultra-high strength deformed aluminum alloy widely used in the aviation industry. It is characterized by good plasticity after solution treatment and particularly good heat treatment strengthening effect. It has high strength below 150℃, and has particularly good low-temperature strength. The plasticity in the annealed and freshly quenched states is slightly lower than that of 2A12 in the same state. It is slightly better than 7A04. The plate is static fatigue and notch sensitive, and has excellent stress corrosion properties. Among 7A04, 7075T651 is particularly top-grade and is known as the best product among aluminum alloys. It has high strength and is far better than mild steel. This alloy has good mechanical properties and anodic reaction, and is a typical aviation aluminum.

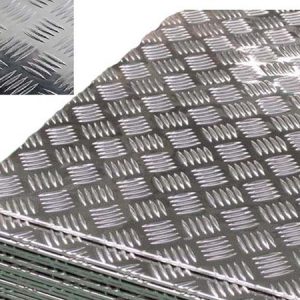

该 7075 varieties are divided into plates, thick plates, stretched tubes, extruded tubes, 杆, 形状, rows, wire rods, rolled or cold-processed bars, and cold-processed wire rods. The states include O state, T6 state, T651 state, T6511 state, T73 state, T7351 state, T7651 state, T76511 state, and H13 state.

典型用途 7075 aluminum are aerospace industry, blow molding (瓶子) 模具, ultrasonic plastic welding molds, golf ball heads, shoe molds, paper molds, foam molding molds, dewaxing molds, 模板, 固定装置, 机械设备, mold processing and other corrosion-resistant high-stress structural parts

Zinc is the main alloy element in 7075. Adding magnesium to an alloy containing 3%-7.5% zinc can form MgZn2 with significant strengthening effect, making the alloy’s heat treatment effect far better than that of aluminum-zinc binary alloys.

铝板 / 板材 7075-T6/T651 通常用于航空航天, 军事, 和汽车应用. 7075 铝 是最强的铝, 具有许多钢材的强度, 同时保留铝的轻质特性和耐腐蚀性.

| 合金 | 脾气 | 厚度 | 宽度 |

| 7075 | T651 | 4-260毫米 | 1200-3800毫米 |

| 7075 | T7651 | 4-260毫米 | 1200-3800毫米 |

| 7075 | T7351 | 4-260毫米 | 1200-3800毫米 |

机械性能

| 合金状态 | 方向 | 厚度 (毫米) | 抗拉强度 | 屈服强度 | 断裂伸长率 | 标准 |

| 7075-T651 | LT | 6-260 | 570-590MPA | 495-515MPA | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560MPA | 480-490MPA | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520MPA | 420-435MPA | 10-12.5 | AMS4078 |

铝 7075 是的成员 7000 系列, 以锌为主要合金成分,以其极高的强度而闻名. 然后回火处理可以进一步增强其高机械强度. 这种特性使合金 7075 在航空航天和国防工业中非常受欢迎.

其强度可与多种钢材相媲美, 但它的密度要低得多. 该合金是高应力应用中钢的极佳替代品. 它在承受疲劳压力方面也表现出色, 使其非常可靠, 在上述行业中备受追捧的品质.

合金 7075 仅提供一般的耐腐蚀性, 其化学成分中含有少量铜的结果. 它还具有合理的机械加工性和较差的成型性和焊接性. 这种合金的另一个缺点是,由于其极高的强度,与其他铝合金相比,其成本相对较高.

-

-

-