描述

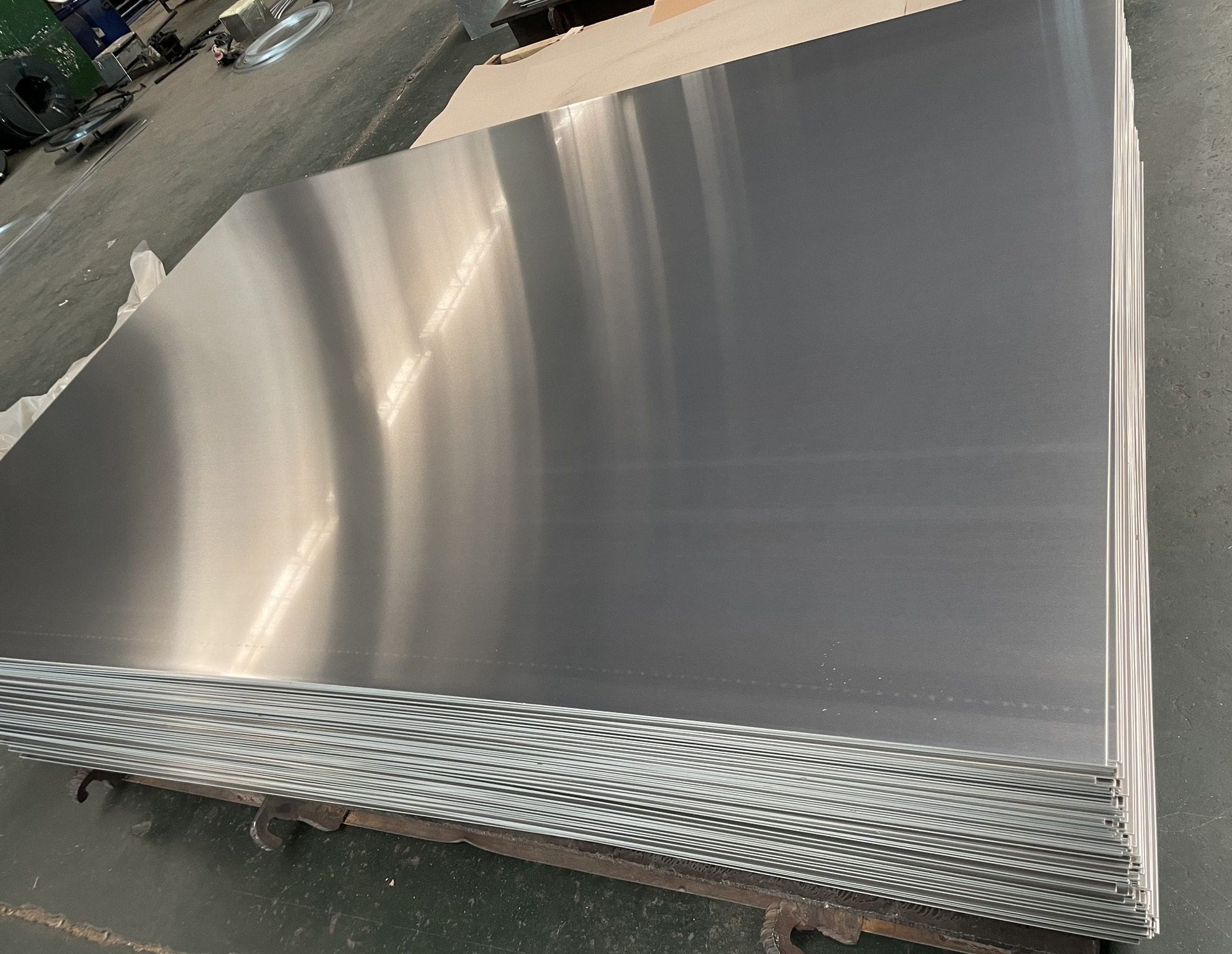

7075 aluminum sheet is a high-strength aerospace aluminum alloy that is commonly used in the manufacture of aircraft and other high-stress applications.

It has excellent strength-to-weight ratio and is resistant to stress corrosion cracking. The alloy is available in various thicknesses and sizes, and can be easily machined and formed. It is also heat treatable, which allows for further strengthening of the material.

7075 铝板 is typically used in the construction of aircraft wings, 机身框架, and other structural components. It is also used in the manufacturing of high-performance sporting equipment, such as bicycle frames and rock climbing gear.

铝板 / 板材 7075-T6/T651 通常用于航空航天, 军事, 和汽车应用. 7075 铝 是最强的铝, 具有许多钢材的强度, 同时保留铝的轻质特性和耐腐蚀性.

| 合金 | 脾气 | 厚度 | 宽度 |

| 7075 | T651 | 4-260毫米 | 1200-3800毫米 |

| 7075 | T7651 | 4-260毫米 | 1200-3800毫米 |

| 7075 | T7351 | 4-260毫米 | 1200-3800毫米 |

机械性能

| 合金状态 | 方向 | 厚度 (毫米) | 抗拉强度 | 屈服强度 | 断裂伸长率 | 标准 |

| 7075-T651 | LT | 6-260 | 570-590MPA | 495-515MPA | 10-13.5 | GB/T3880 |

| 7075-T7651 | LT | 6-102 | 550-560MPA | 480-490MPA | 10.5-12.5 | AMS4045K |

| 7075-T7351 | LT | 6-102 | 500-520MPA | 420-435MPA | 10-12.5 | AMS4078 |

铝 7075 是的成员 7000 系列, 以锌为主要合金成分,以其极高的强度而闻名. 然后回火处理可以进一步增强其高机械强度. 这种特性使合金 7075 在航空航天和国防工业中非常受欢迎.

| 典型机械性能 7075 铝板 | ||||

| 脾气 | 厚度

(毫米) |

抗拉强度

(MPA) |

屈服强度

(MPA) |

伸长

(%) |

| T6 | 1~3.2 | 540 | 470 | 8 |

| T6 | 3.2~6.3 | 540 | 475 | 8 |

| T651 | 6.3〜12.5 | 540 | 460 | 9 |

| T651 | 25〜50 | 530 | 460 | — |

| T651 | 60~80 | 495 | 420 | — |

| T651 | 90〜100 | 460 | 370 | |

其强度可与多种钢材相媲美, 但它的密度要低得多. 该合金是高应力应用中钢的极佳替代品. 它在承受疲劳压力方面也表现出色, 使其非常可靠, 在上述行业中备受追捧的品质.

合金 7075 仅提供一般的耐腐蚀性, 其化学成分中含有少量铜的结果. 它还具有合理的机械加工性和较差的成型性和焊接性. 这种合金的另一个缺点是,由于其极高的强度,与其他铝合金相比,其成本相对较高.

瑞威尔 MFG or RuiYi Aluminum provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting the challenges of the future.

Quality could full meet AMS aviation standard.

标准

Bare: AMS QQ-A-250/12, 学士学位 2 L95, AMS 4038, AMS 4045, AMS 4039, AMS 4049, AMS 4044, AMS 4045, AMS 4078, QQ-A-250/24, AIR 9048.690, AIR 9048.700, AIR 9048.710, AIR 9049, 等等.

AlClad: AMS QQ-A-250/13, 学士学位 2 L88, AMS 4046, AMS 4048, AMS 4049, QQ-A-250/18, QQ-A-250/25, QQ-A-250/26, 等等.

We have passed AS9100, OHSAS 18001 and other certifications required by the aviation industry, providing a strong guarantee for the quality of aerospace materials produced by our company.

Accreditations

AS9100

OHSAS 18001

ISO14001

ISO9001

NADCAP HT

NADCAP NDT

IATP16949

In what application scenarios can 7075 aluminum alloy not replace other materials?

7075 铝板和 铝棒 are important members of aluminum alloy materials. They are widely used in many fields due to their high strength, 良好的机械性能, excellent corrosion resistance and wear resistance.

首先, 7075 aluminum alloy is a high-strength heat-treatable alloy. Its strength is far greater than that of ordinary hard aluminum, and it has excellent weldability and corrosion resistance. This makes it irreplaceable in aerospace, 汽车制造, shipbuilding and other fields.

In the aerospace field, 7075 aluminum sheet plate and aluminum rods are often used to manufacture aircraft parts, such as wings, fuselages, engine casings, 等等, because they can significantly reduce the weight of aircraft and improve flight performance and fuel economy.

In automobile manufacturing, they are used to make body parts, 轮子, suspension systems, 等等, aiming to improve the overall performance and fuel economy of the car.

其次, 7075 aluminum plates or aluminum sheets and aluminium rods also have good processing performance and wear resistance, which makes them useful in the fields of electronic products and sports equipment manufacturing.

In the field of electronic products, they are used to manufacture electronic equipment casings, heat sinks and other components to improve the heat dissipation efficiency and protection performance of the equipment.

In the manufacturing of sports equipment, 7075 aluminum sheets and aluminum rods are often used to make sports equipment such as hiking poles, 自行车车架, poles, and ski poles due to their lightweight and durable properties.

7075 aluminum alloy is widely used in many fields due to its high strength, 耐磨性, 优异的耐腐蚀性, and good electrical and thermal conductivity.

Especially in situations where high material performance requirements are required, 7075 aluminum alloy shows its unique advantages.

具体来说, in the aerospace field, which has extremely high requirements for the strength and corrosion resistance of the material, 7075 aluminum alloy has become an ideal choice due to its excellent performance.

例如, 7075 aluminum alloy plays an irreplaceable role in the manufacturing of key components such as aircraft parts, 翅膀, fuselages and engine casings.

相似地, in the field of automobile manufacturing, 7075 aluminum alloy materials are often used in components such as high-strength bolts, aluminum alloy cylinders, and automobile bodies.

-

-

-