描述

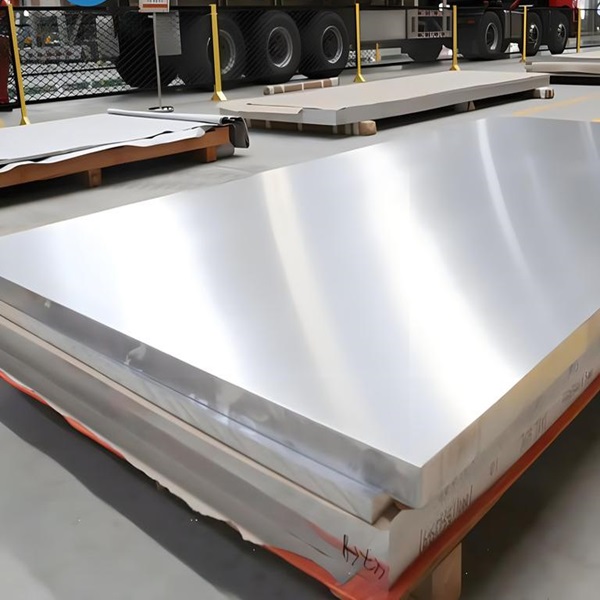

Aerospace aluminum plates and aluminum rods are commonly used materials in the aerospace field and have the characteristics of high quality and high performance.

Aerospace aluminum plate is a high-strength, high-hardness aluminum plate, usually made of 7 系列铝合金, 如 7075 铝合金.

The surface treatment of aerospace aluminum plate usually uses anodizing or spraying technology to improve its corrosion resistance and appearance quality but depends on customer’s specific request.

Aerospace aluminum plates are lightweight, 高强度, high-rigidity and high-durability, and can withstand extreme temperatures and pressures, so they are widely used in the aerospace field.

Aerospace aluminum rods are also a commonly used aviation material, usually made of 6 series or 7 系列铝合金, 如 6061 铝合金.

This aluminum rod has high strength, high rigidity and good processing properties, and can meet the high requirements of the aerospace field.

Aviation aluminum rods are mainly used to manufacture aircraft parts, engine parts and aerospace vehicle structural parts.

Aviation 铝板 and rods need to be of high quality and high performance, and require strict quality control and performance testing during the production process.

与此同时, the surface treatment and processing technology of aviation aluminum plates and aluminum rods also need to meet high standards to ensure that their appearance quality and performance meet requirements.

Aviation aluminum alloy is an aluminum alloy material specially developed for the aviation industry. It has the characteristics of high strength, high rigidity, light weight and corrosion resistance.

Due to its excellent performance in extreme environments such as high temperature, high stress and high corrosion, aviation aluminum alloy has been widely used in the aviation industry.

Aviation aluminum alloys have higher strength and rigidity than ordinary aluminum alloys, while maintaining good plasticity and processing properties.

此外, 航空铝材 alloys also have good corrosion resistance and fatigue resistance, and can maintain their performance for a long time under complex environmental conditions.

Common aviation aluminum alloys include 7 series aluminum alloys and 6 系列铝合金.

7 series aluminum alloy is a high-strength, high-hardness aluminum alloy, 如 7075 铝合金, which is mainly used to manufacture important structural parts such as aircraft frames and skins.

6 series aluminum alloy is a medium-strength, medium-hardness aluminum alloy, 如 6061 铝合金, which is mainly used to manufacture aircraft parts and engine parts.

The production of 航空铝材 alloys requires multiple processes, including smelting, 铸件, 滚动, heat treatment and surface treatment.

在生产过程中, strict quality control and performance testing are required to ensure that the quality and performance of aviation aluminum alloys meet the requirements.

与此同时, the surface treatment of aviation aluminum alloy is also very important, which can improve its corrosion resistance and appearance quality.

Aerospace aluminum alloys are available in a variety of grades and states, depending on their manufacturing standards and uses. The following are some common aviation aluminum alloy grades and states:

7075 aluminum alloy is a high-strength, high-hardness aluminum alloy widely used in the aerospace field. 它具有优异的机械性能, corrosion resistance and fatigue resistance.

7075 aluminum alloy can be heat treated in different states such as T6 and T73 to improve its overall performance.

6061 aluminum alloy is a medium-strength, medium-hardness aluminum alloy that is also widely used in the aerospace field. It has good plasticity, welding performance and processing performance.

6061 aluminum alloy can be heat treated in different states such as T4 and T6 to improve its hardness and mechanical properties.

Typical Application of Aviation aluminum Plate:

| 物品 | 年级 | 脾气 | 应用 |

| 1 | 2024 | 该,T351、T851 | 机身结构, 机翼拉伸组件, 抗剪腹板, 刚性结构截面 |

| 2 | 2014 | T851、T351 | 机身加工部件, 舱壁, 高性能军用飞机的机翼蒙皮和其他结构部件 |

| 3 | 2324 | T39 | 商用飞机下机翼蒙皮和翼盒组件 |

| 4 | 7050 | T7651,T7451 | 机身环, 框架 |

| 5 | 7150 | T6151,T7751 | 要求耐高压的大型商用飞机上翼蒙皮, 民用和军用飞机上机翼加强板和下水平安定面面板 |

| 6 | 7055 | T7751 | 上翼结构, 水平安定面, 龙骨梁, 座椅轨道, 货运滑道 |

| 7 | 7075 | T651, T7651,O,T7351 | 飞机结构件要求高强度, 中等韧性和中等耐腐蚀性 |

| 8 | 7475 | T651、T7351 | 机身蒙皮, 翼皮, 翼梁, 机身舱壁 |

What are main Application of aluminum alloy in aviation field?

铝合金, as a lightweight, 高强度, corrosion-resistant metal material, has been widely used in the aviation field.

1. Aircraft structure

Aluminum alloys are widely used in aircraft structures, including fuselages, 翅膀, tails, 等等. Aluminum alloy has high specific strength, processing performance and corrosion resistance, and can meet the material requirements of aircraft structures.

The main form of aluminum alloy aircraft structure is the welded structure of aluminum alloy plates and profiles, 具有重量轻的优点, 高强度, 和耐腐蚀性.

2. Landing gear

Landing gear is an important part of the aircraft and requires materials with high strength, corrosion resistance and good processing properties.

As an excellent metal material, aluminum alloy is widely used in landing gear manufacturing.

The main form of aluminum alloy landing gear is cast integral landing gear, 具有重量轻的优点, 高强度, 和耐腐蚀性.

3.Engine parts

Aluminum alloys are also widely used in aerospace engines, including turbine blades, compressor blades, discs, 等等.

Aluminum alloy has the advantages of high strength, corrosion resistance and good thermal conductivity, and can meet the material requirements of engine parts.

The main forms of aluminum alloy engine parts are casting and machining, which have the advantages of light weight, 高强度, 和耐腐蚀性.

4.Aerospace components

Aluminum alloys are also widely used in aerospace components, including satellite structures, rocket fuel tanks, 等等.

Aluminum alloy has the advantages of high strength, corrosion resistance and good processing properties, and can meet the material requirements of aerospace components.

The main form of aluminum alloy aerospace components is the welded structure of aluminum alloy plates and profiles, 具有重量轻的优点, 高强度, 和耐腐蚀性.

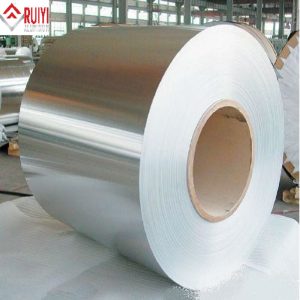

5.Aviation foil

Aviation foil is an aluminum alloy foil with a thickness less than 0.2mm. It has the advantages of high strength, 轻的, 和耐腐蚀性.

Aviation foils are mainly used as skin materials and structural materials in aircraft manufacturing, which can improve the performance and life of the aircraft.

The main form of aviation foil is aluminum alloy rolled foil, 具有重量轻的优点, high strength and corrosion resistance.

简而言之, aluminum alloys are widely used in the aviation field, including aircraft structures, landing gears, 发动机零件, aerospace components and aviation foils.

Aluminum alloy has the advantages of high strength, 轻的, 和耐腐蚀性, and can meet the material requirements of the aviation field.

In the future, with the continuous development of aviation technology, the application of aluminum alloys in the aviation field will be more extensive and in-depth.

瑞威尔 MFG是中国专业的金属材料供应商, 我们可以供应铝, 防锈的, 镀锌钢, 冷轧钢, 涂层铝, 铜板, 我们只与号码合作 1 中国制造商,让我们的客户对我们的质量感到满意和满意,而不仅仅是有竞争力的价格.

-

-

-